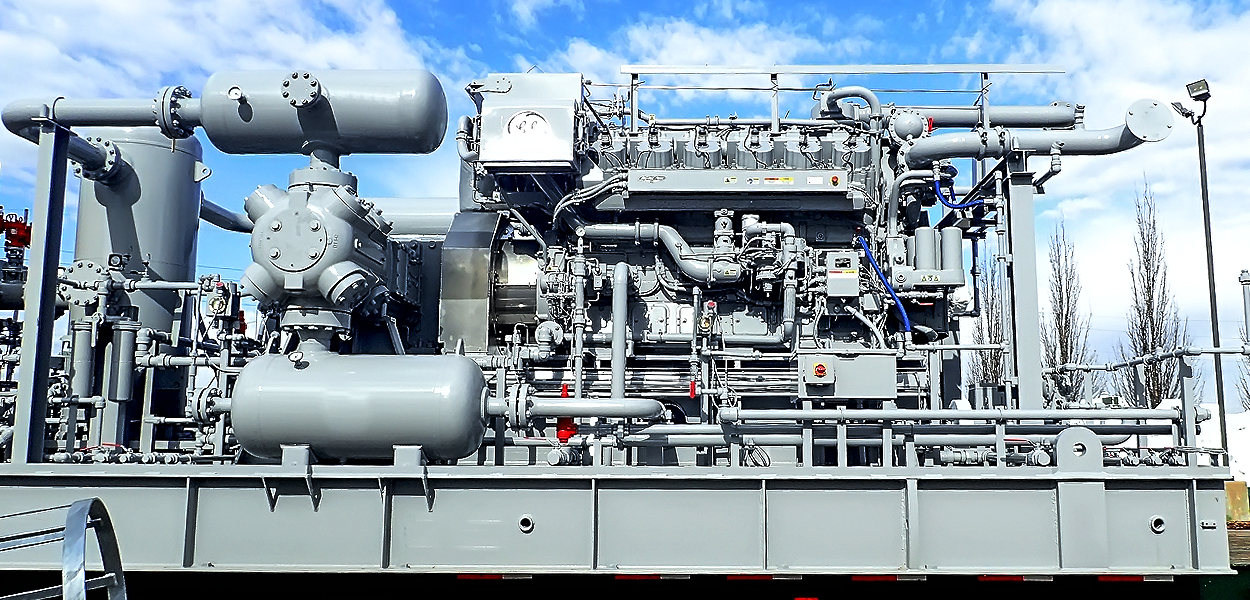

Gas Compressor Package Project

Mechanical rotating equipment projects typically begin with a feasibility study to assess the scope and technical requirements of the project. This is followed by design and engineering, where the project team develops detailed specifications and drawings for the equipment. After design approval, procurement and fabrication of the equipment take place, followed by assembly and installation.

During the project execution phase, testing and commissioning of the equipment are carried out to ensure that it meets the required standards and specifications. Once the equipment is commissioned, ongoing maintenance and repair services are provided to ensure reliable and efficient operation.

“Powered by Waukesha Gas Engine and Ariel Gas Compressor, we completed mechanical rotating equipment project.”

Common challenges that may arise during mechanical rotating equipment projects include managing project timelines, ensuring compliance with technical standards and regulations, managing project risks, and ensuring effective communication and coordination among project stakeholders. Effective project management and a skilled and experienced project team are essential for successful project execution and delivery.